Search this site

Effective zone patch up

How long does it take to make ready?

It is not easy for everyone since it needs caution and experience.

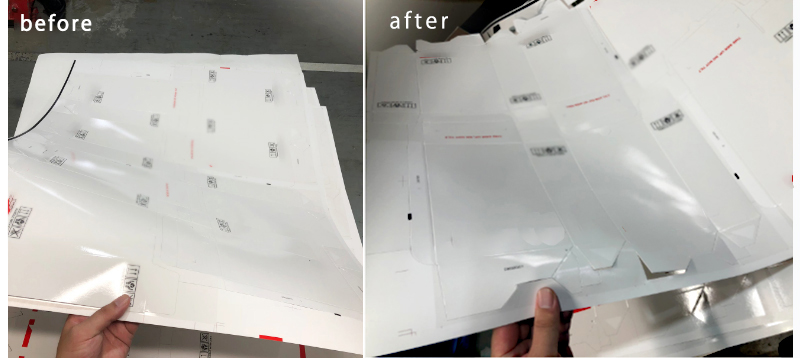

For example, gripper side is uncut but gripper-end side is cut well.

Sensitive patch up is necessary to keep quality.

Over-pressure and rough patch up lead to big trouble like paper dust which comes from dull blade edge and paper crack.

In worst case, low quality products will be returned and take time for inspection.

You need to find solution to keep blade edge sharply under this situation.

Operators might not feel like patch up, patching takes time, hard to run as schedule…

“If I increase pressure with well balanced, I can save time.

Any simple solution for make ready?

Save time with zone patch up

Technique to prepare in advance.

Would you try Zone patch sheet? It is quite simple to use.

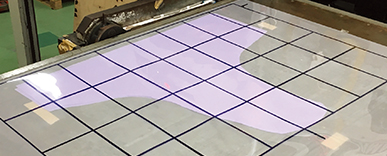

Put this sheet on less pressure area of chase as picture above, then arrange makeready sheet or film as usual.

Without special process, it will adjust balance of less pressure area.

It is effective to pile up Zone patch up sheet depending on cut-uncut situation.

Dieboards always set to gripper side regardless of product size.

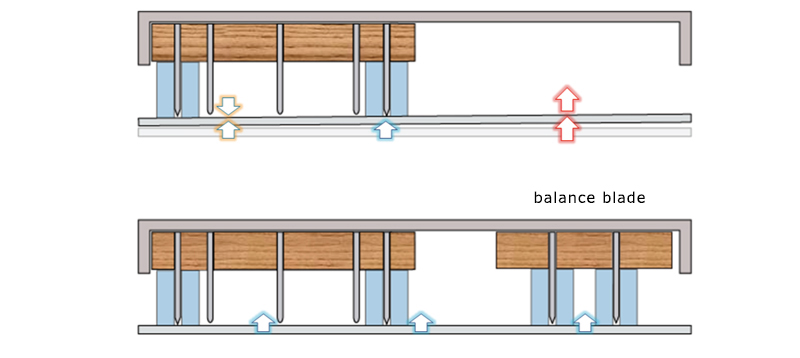

There is gap between gripper side and gripper-end.

As a solution, balance blade or creasing rule is common.

Saving time for makeready need to find piled patch tape area from makeready sheet and keep well balance or grasp machine balance as picture.