Search this site

- < Improve creasing line and reduce crack and torn-surface

- How to arrange die cutting with round and long oval hole >

Perforation blade diecut

What is perforation blade?

Perforation is a common blade for special diecut.

You would often see this cutting process in the boxes of chocolates, Amazon/eBay and tissues. It is frequent to be touched in our life.

The function is to cut and open boxes easily, however, it needs to keep strength not to be cut during transport. Because of these balances, it is the one of difficult processing.

It would be hard to select appropriate blades and processing in diecut.

We would like to introduce types of blades and processing, points and perforation pitch etc. in this page.

Perforation, cut-crease, zipper

There are 3 types of perforation processing.

・Perforation

・Cut-crease

・Zipper

Each processing has different function and need to select different blades.

We would like to explain each function.

①Perforation

Perforation blade is for packaging open area or creasing line.

The main function is to break some parts easily or make sharp creasing line.

It is used in many things like chocolate boxes and tissue boxes that are often seen around our life.

Recent tissue boxes have double perforation blades as below pictures to be cut smoothly.

Perforation blades have various pitch and you need to select carefully.

<reference article>

Perforation rule Combination rule pitc

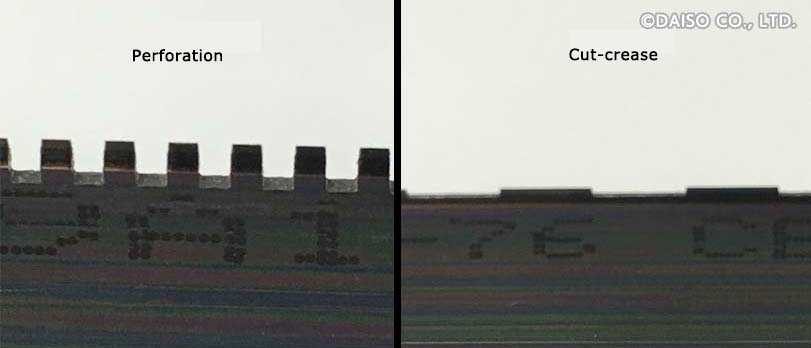

②Cut-crease

Cut-crease looks similar to perforation, literally it is combination blades cut and crease.

The purpose is easier creasing and it is used for reverse crease and 180 degree folding.

You may think perforation blade is no problem for better creasing, however, cracks could occur on the sheet surface because sheet surface is pulled in the case of perforation.

Cut-crease puts creasing line as below picture. This makes easy and smooth folding.

We suggest our G-tape creasing matrix G type as reverse crease as well.

<reference article>

Reverse creasing by G-tape

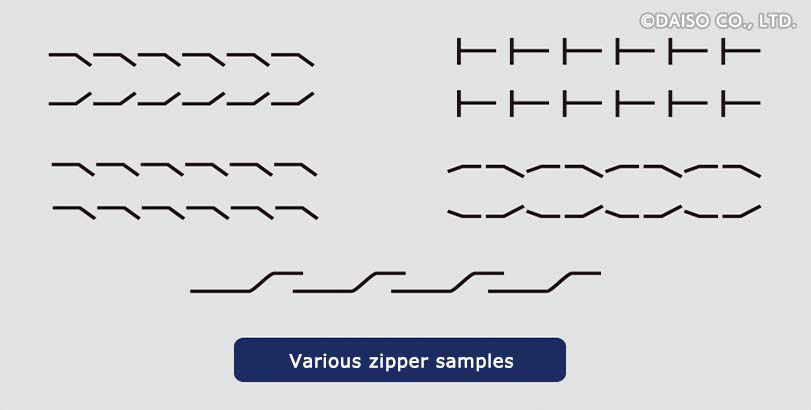

③Zipper

Zipper is for packaging open area.

It looks similar with perforation and is mixed up. The function is to open and break boxes like chocolate boxes.

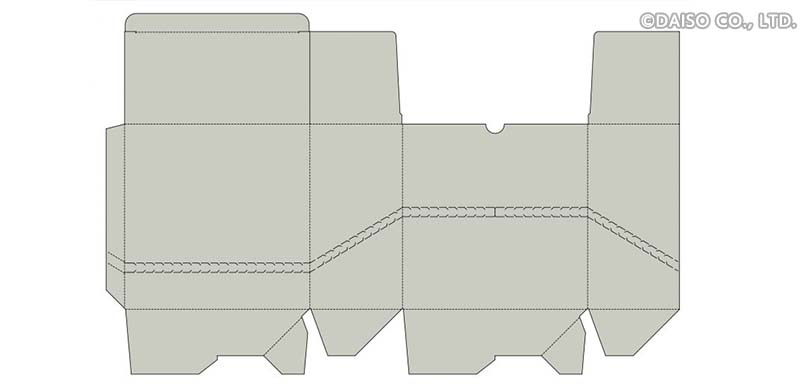

(Box design with zipper)

There are various types of Designs/pitches to show the originality.

How to make special blades

Blade manufacturers provide these blades as their standard models and their custom-made ones from customer requests.

・Standard blade

It is made from 1 straight blade and easy to put in plywood.

It is common to be used with beverage boxes and delivery boxes that the specification is fixed in corrugated boxes.

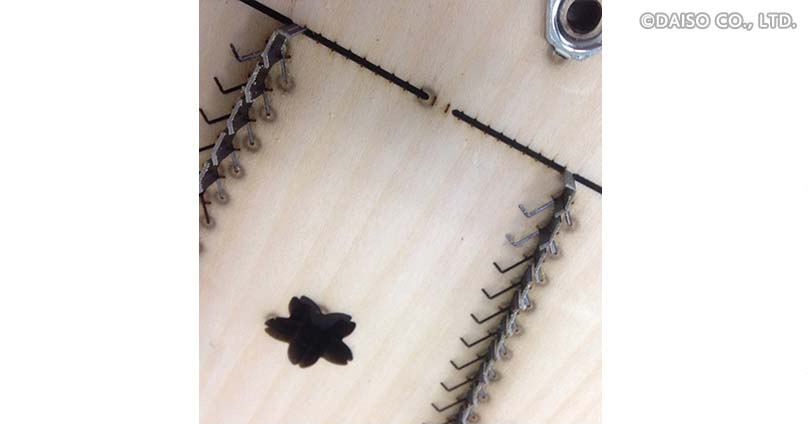

・Custom-made blade

Short blade is bent like dogleg each and put each in plywood.

Diemaking takes time, however, it would be the original shapes which is used to functionality, design and package branding.

Short blades have the risk of separating from plywood during diecut. In order to avoid this trouble, high skill is needed.

・Auto-bender

It was standard that blade-cut/bend by hand before, then nowadays auto-bender is common to improve productivity and precision.

DAISO has lots of auto-benders to arrange various types of blade processing.

(Samples by auto-bender)

Points of perforation pitch

As our explanation, special blade processing is different each depending on function.

It is hard to select blade pitch always, it is the distance between blade edges.

If pitch distance is too short for easy opening against sheet condition, it might make rejected products that will be torn without enough pressure.

It should be selected by paper thickness, cutting position and lamination materials apart from its function.

Even correct setting in terms of paper thickness, it might be tough to be torn or be cut in a wrong direction in your experiences.

On the contrary, when it is too easy to tear, cutting area is open in the display shelves or delivered goods are open before customers open. These bad-looking situations could lead to complaint in worst case.

There is no typical answer, however, this would be the clue for the selection of perforation.

Selection of perforation of pitch

As our explanation, special blade processing is different each depending on function.

【Points】

1.Paper fiber direction

2.Distance of perforation edges←In the case of long distance, strength will be lower.

3.Diagonal direction perforation

4.Cutting plate creasing tools like creasing matrix and counter plate etc.

5.Condtion of display and transport (the way of piling up)

【Test way】

1.Put perforation cut in actual sheet and try to cut and fold.

2.Diecut actual sheet with another die which you replace balance blade with perforation for testing.

For your reference, this perforation chart could be helpful.

It consists of folding and cutting.

<reference article>

Perforation rule Combination rule pitch

Conclusion

Perforation and continuous cuts processing is one of difficult skills which need technique and experiences. On our 50 years knowhow and experience, DAISO suggest the proper pitch and processing.

Feel free to ask any question if you have trouble of perforation etc. to meet customer request.