Search this site

About Nick trouble ➡ How to solve “Nick trouble”

Do you have any trouble in making nicks, inconsistent depths and width, which are made by unskillful operators?

Those nicks might cause damages or defects of your products.

It is important to make nicks in right place with width and depth in order to prevent troubles.

It is also important to use the correct tool to make nicks.

There are various tools and methods in the market,

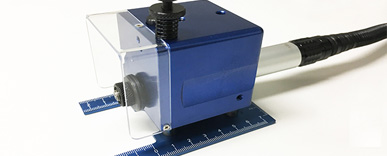

We recommend “DAISO Nick Grinder”.

DAISO Nick Grinder is designed to make consistent nick quality so that you might face less defects or troubles.

Since there is little individual difference between people,

product defects and troubles due to variations in nicking can be improved.

Pay attention to appropriate locations, numbers and sizes for nicking. Please use the correct device that minimizes human mistakes.

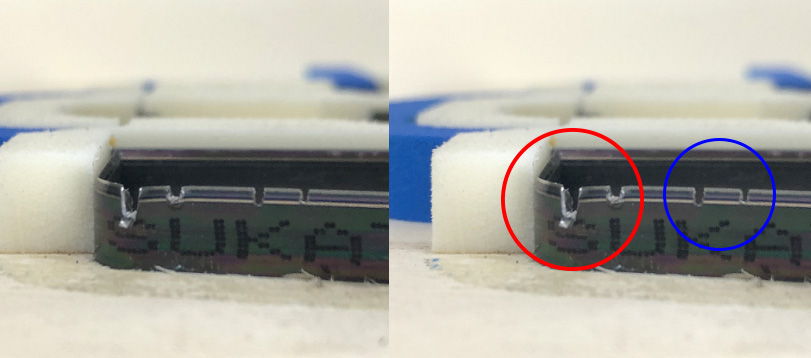

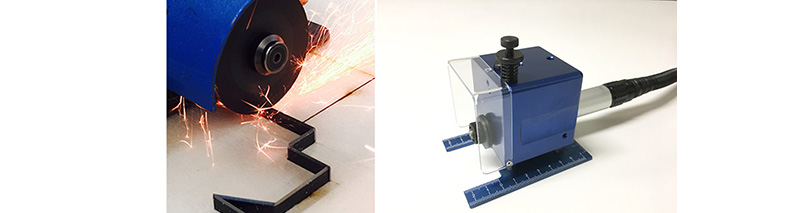

See the above figure.

The figures on the left shows the nicks made with a minus-head screwdriver.

The blade is deformed or damaged.

With this damaged blade, your product may be scratched, or it may become defective, and the blade shall need replacement. And in the worst case, your customer complains to you.

The figures on the right (blue circles) are 0.5mm and 0.3mm nicks made by our Nick grinder.

Since nicks are made with a constant force, all nicks are made consistently with less human mistakes.

Advantage of DAISO Nick Grinder

1. You can make correct depth for each nick thanks to “stroke limitter” of the grinder.

2. You can keep correct width of each nick by changing grinding discs of different thickness

3. Grinding discs assure clear nicks without damaging blades.

If you have any difficulties in making nicks, please consider to try “DAISO Nick Grinder”.