Search this site

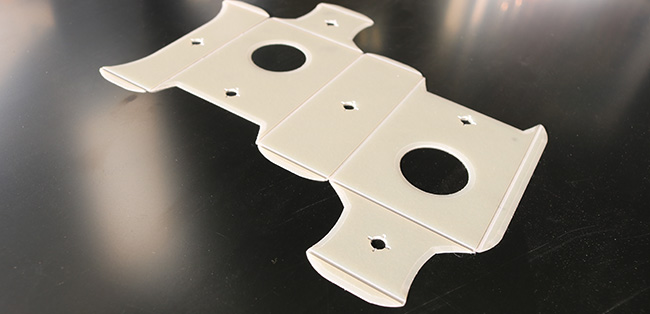

- Counter plate, pertinax

- Counter plates pertinax

Counter plates pertinax

Unit = mm

APP

Features

- Flatbed diecutting up to approx. 100,000 press.

- Self-adhesive on the back.

Specification

| Name | Thickness | Size |

|---|---|---|

| APP 0.4 | 0.4 | 680 x 1030 |

| APP 0.5 | 0.5 | 680 x 1030 |

| APP 0.6 | 0.6 | 680 x 1030 |

| APP 0.7 | 0.7 | 680 x 1030 |

| APP 0.8 | 0.8 | 680 x 1030 |

| APP 1.0 | 1.0 | 680 x 1030 |

GH-Plate

Features

- Flatbed diecutting up to approx. 200,000-500,000 press.

- Self-adhesive on the back.

Specification

| Name | Thickness | Size |

|---|---|---|

| GH-Plate 0.4 | 0.4 | 1020 x 1020 |

| GH-Plate 0.5 | 0.5 | 1020 x 1020 |

| GH-Plate 0.6 | 0.6 | 1020 x 1020 |

| GH-Plate 0.7 | 0.7 | 1020 x 1020 |

| GH-Plate 0.8 | 0.8 | 1020 x 1020 |

| GH-Plate 1.0 | 1.0 | 1020 x 1020 |

GN plate

Features

- The highest level of durability made in Japan(700,000-1,000,000 shots).

- Less likely to warp, expand and contract.

- Stable cutting process and reduction of incidental work.

- Reduction of running cost (Less replacement due to deterioration).

- Damage deduction in deburring process.

Specification

| Name | Thickness | Size |

|---|---|---|

| GN-Plate 0.4 | 0.4 | 1020 x 1020 |

| GN-Plate 0.5 | 0.5 | 1020 x 1020 |

| GN-Plate 0.6 | 0.6 | 1020 x 1020 |

| GN-Plate 0.7 | 0.7 | 1020 x 1020 |

| GN-Plate 0.8 | 0.8 | 1020 x 1020 |

| GN-Plate 1.0 | 1.0 | 1020 x 1020 |